HARDWARE DESIGN

SpotBot’s aluminum and steel frame and overall architecture was built in order to simulate a traditional barbell-and-rack exercise system, allowing for lifts such as bench press, shoulder press, curls, deadlift, and squat. The weight bar is attached at both ends to a length of 750 pound test paracord, which is routed upwards around a set of pulleys that isolate the cords’ tension on parallel beam load cells. The load sensors connect through instrumentation signal amplifiers to an Arduino, which handles the data acquisition and input/output functionality. Following the routing around the sensor pulley system, the paracord is then coiled around a spindle, which is coupled to a 24 Volt, 5 Newton-meter electric motor by a 4:1 chain-drive transmission. The motor is controlled by a unidirectional motor speed controller, which itself is coupled to a 750 Watt power supply. The entire hoisting system is designed to lift a maximum of 300 pounds.

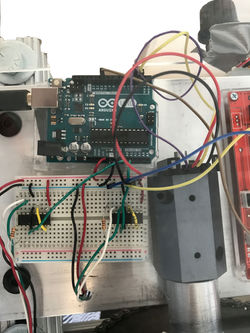

Arduino and BreadboardLow-power load cell signal amplification circuit and microcontroller that allows computerized actuation of system. The Arduino acts as a data acquisition unit from the load cells and encoder, as well as digital output signal generator to actuate the motor driver board. |  Motor Driver Board24 V motor speed controller, allowing fine motor control from Arduino’s pulse width modulation signal output. |  Motor, Gear, and SpindleHoisting system coils 750 lb-test paracord around a spindle driven by a brushed DC motor and 4:1 chain-driven transmission. Motor mount slides and locks to tension the chain. |

|---|---|---|

EncoderQuadrature-signal capacitive rotary encoder mounted to spindle shaft, capable of measuring vertical position, velocity, and acceleration of the weight bar. This sensor allows SpotBot to detect lifting failure and collect key performance statistics. |  Power Source750 W AC to DC switched-mode power supply. |  Load Cell Sensor SystemCantilever beam load cell and pulley system that allows for isolated measurement of cord tension, for use in feedback control system and performance data calculations. Plate-mounted low friction roller bearings support the drive shaft. |